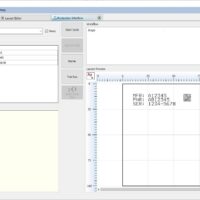

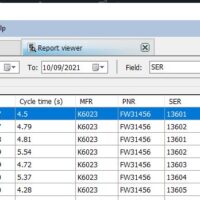

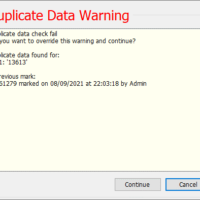

Traceability Software

Our marking and traceability software can be used across our machinery product range to add Windows based software control to all our marking machines.

It is available in five different tiers depending on your individual requirements.