Welcome To Pryor Technology UK

The Experts in Marking and Traceability

Which website would you like to visit first…

Give your workflow the

Pryor Touch

The World’s most powerful lightweight portable dot peen marking machine

A Custom

Marking Solution

That can have huge benefits to your manufacturing process

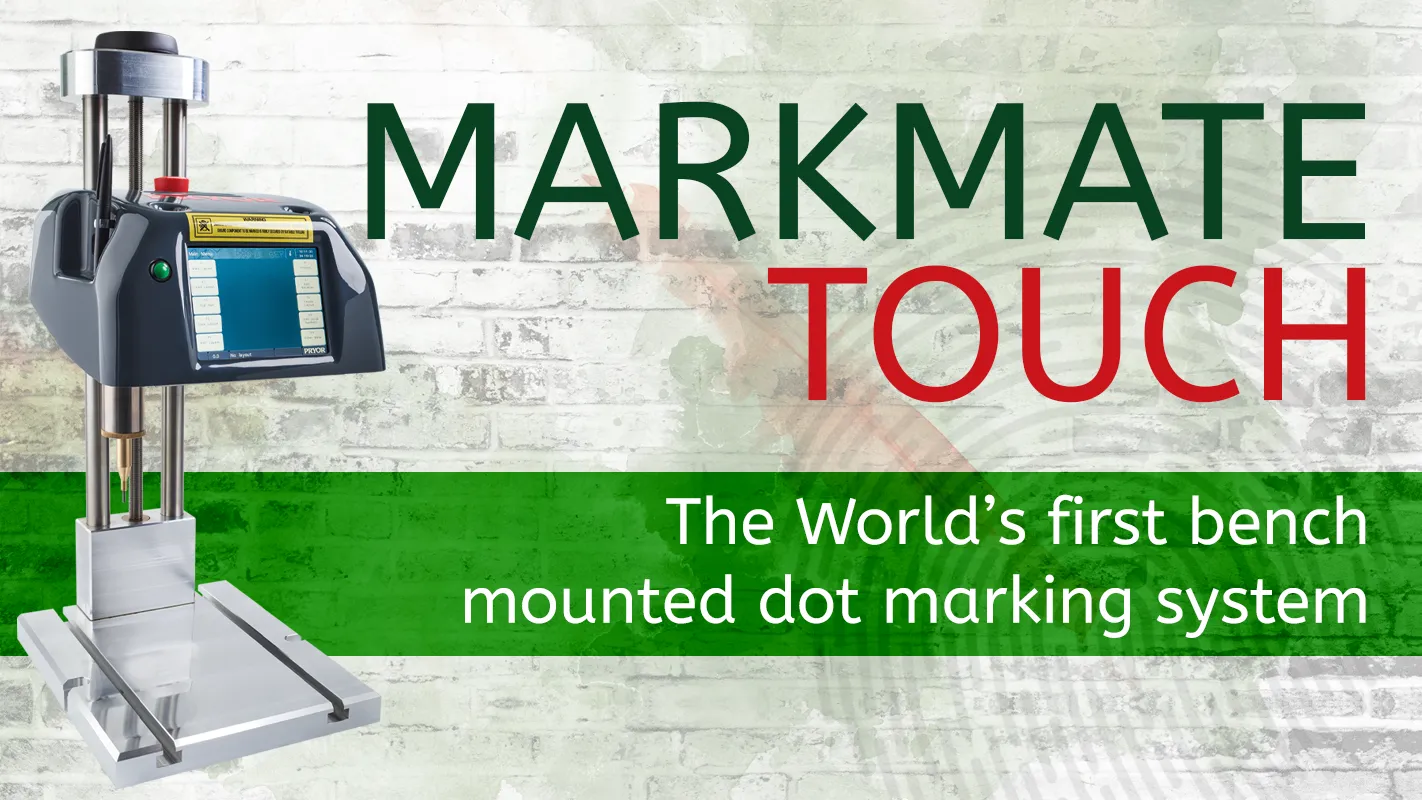

MarkMate

Touch

The World’s first bench mounted dot marking system

Custom

Stamps

We offer bespoke marking solutions for all industries

Latest News

Pryor and the Apprentice

From completing his apprenticeship (1843 to 1848) to becoming owner of the business less than a year later, Edward Pryor... read more

Dot Peen and Laser Marking Vs Labelling or Inkjet Printing for Production Lines

In the fast-paced world of manufacturing, efficiency, durability, and accuracy are paramount. Every component, product, or package must be clearly... read more

40 Years at Pryor for Gary Fletcher

Congratulations to Gary Fletcher who has been with us here at Pryor for an amazing 40 Years this month. We... read more

35 Years at Pryor for Craig Holmes

Congratulations to Craig Holmes who has been with us here at Pryor for an amazing 35 Years this month. We... read more

10% off Online Handtools Orders this March

It's less than 175 days until we're 175 years old. We’ve started the celebrations early. Until the End of March... read more

Choosing the right marking technology: Dot Peen vs. Laser Marking

In the domain of direct part marking, Dot Peen and Laser Marking stand out as leading technologies, each presenting unique... read more

Pryor and the South Rural Task Force

Pryor have recently supplied 3 new PortaDot 60-30’s to the South Rural Task Force. The taskforce covers the rural areas... read more

Proud to be Pryor

For the 2020’s at least – Sheffield has a typical UK City Centre: Bourgeoning residential blocks and apartments, boulevards of bars... read more